866-685-4443 | Get in Touch Online ...

The 94-Kilowatt Duct Heater

Tunnel ovens: perhaps you've never heard of them; perhaps you use one every day. Either way, tunnel ovens are one more area where you see one of the central problems of industrial electric heating crop up. That problem is: how do you fit a lot of heat-generating capacity into a small amount of space? Here at O.E.M. Heaters, we've helped solve that problem with a new, precisely engineered, highly space-efficient air heater.

The problem

A tunnel oven, essentially, consists of a chamber of heated air with a conveyor belt running through it. The heat is supplied by a duct heater outside the chamber itself – the heater brings the air to temperature, and blowers circulate the air into the oven chamber. Tunnel ovens can be fairly large pieces of equipment, but they do need to fit within a certain size. That's what led to us getting contacted in 2014 by a manufacturer of tunnel ovens and other capital equipment – they had a limited space in their design, and wanted to fit a more powerful, more reliable heater into it.

The application's previous heater was already high-powered, at 78 kilowatts, but to get a faster throughput rate of pieces through the oven, the manufacturer wanted to raise the power to 94 kilowatts. (To put that in perspective, the average American home draws about 1.2 kilowatts.) They also hoped we could find some way to make the heaters last longer than the ones they had been using, which tended to burn out after a disappointingly short time.

Designing a heater

The space we had to work with was just 40 × 10 × 15 inches, roughly as large as a tall kitchen cupboard. We knew we needed 94 kilowatts, and the heater also needed a temperature sensor for safety circuitry, as well as a design that would let air circulate freely. With all our constraints known, we set about figuring out how to build a heater.

In a heater so large, we knew one of the primary considerations would have to be designing heating elements that combined length and durability – often a difficult balance to strike. From previous experience (for example, our Navy truck cab heater), we knew finned Incoloy tubular elements would be both resistant to burnouts and efficient at dispersing heat. This would use the entire available space most efficiently, not to mention solving the burnout problem that had plagued the old ceramic-channel strip heaters, which had been built longer than their design could tolerate.

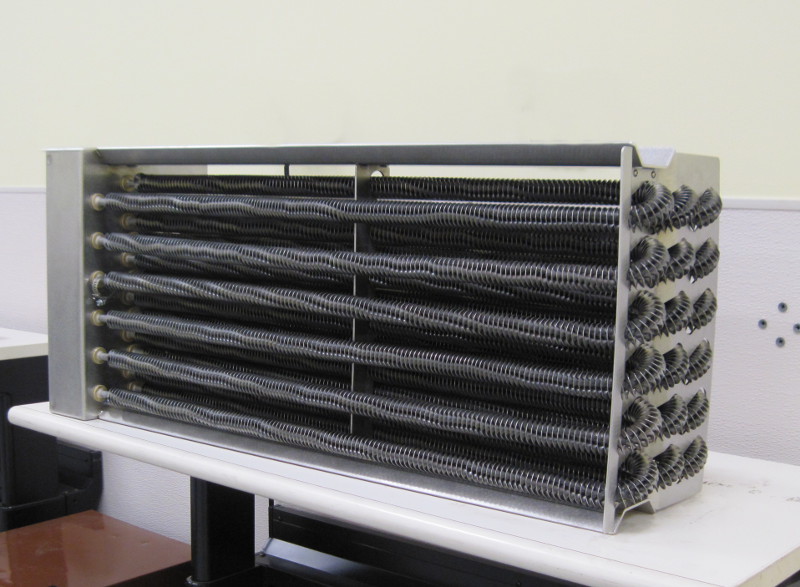

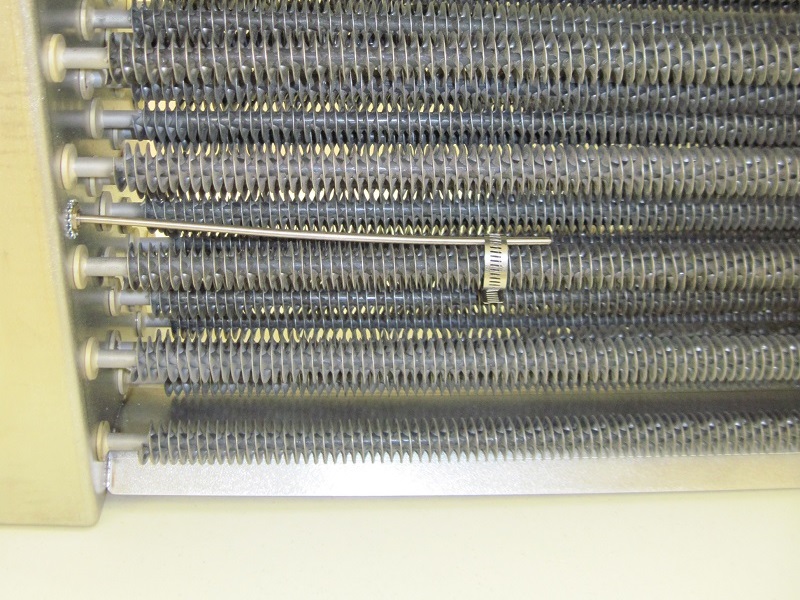

Thus, we had extra-long, U-bent elements specially made, and arranged 18 of them in each heater, in a tightly grouped configuration (see above) that keeps the elements as close together as possible while still preventing them from touching and creating hot spots, which would cause overheating and failure. To keep the elements in place, we designed a custom-tooled 12-gauge stainless steel chassis, structurally reinforced to resist any physical shocks during shipping or installation. A long, rigid RTD (resistance temperature detector) was added to sense the temperature at the hottest spot in the heater, providing a high-limit safety shut-off function. Then, with the addition of some heavy-gauge wiring for high currents and a control box, the heater was complete.

Click an image to view larger in new window.

These heaters have proved reliable and have allowed our customer to significantly speed up the tunnel oven's belt speed. We're receiving regular orders for more of them, and we're happy to have another satisfied customer.

What we can do for you

This is just one example of the value-added engineering we offer (for more, see our Case Studies). O.E.M. Heaters is not just a heater supplier; we also draw on over a century of total heating engineering experience to create custom solutions for difficult applications. We've seen many different ways heaters can fail, or simply not work well enough, and we're skilled at avoiding these problems.

When it seems like there's no heater available for your application, give us a call at (866) 685-4443 or email us at sales@oemheaters.com. As long as it's physically possible, we can probably build the heater you need – at a reasonable price, and with friendly and communicative service. We look forward to solving your heating problem soon.