866-685-4443 | Get in Touch Online ...

Finned Tubular Heaters

Finned tubular heaters are custom-made to fit your application, and are designed for applications where tubular heaters are exposed to forced convection. Placing fins around tubular heaters increases their surface area and improves heat transferring capacity. Finned tubular heaters, compared to regular tubular heaters, run at lower surface temperatures for the same watt densities when placed in identical air streams. Finned tubular heaters are built to order due to individual application requirements. Please call us at (866) 685-4443, send us an e-mail, or fill out a contact form and we can get your quote started right away!

Applications

- Dryers

- Recirculation ovens

- Fan-forced heaters

- Heat treating and annealing

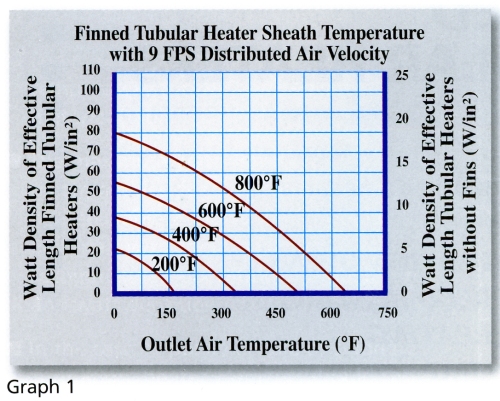

Graph 1 compares watt density, outlet air temperature, and the speed of air flow for regular and finned tubular heaters. Finned tubular heaters are not recommended for applications where outlet air temperatures exceed 600°F.

Construction

The sheath material of a finned tubular heater and its watt density are critical factors that affect its durability. The standard finned tubular heaters are made of steel sheath and steel fins (750°F maximum surface temperature) since steel is very efficient in heat transfer. Finned tubular heaters have a plain-surface finish. For corrosive environments or high-temperature applications (above 750°F), finned tubular heaters can be made with stainless steel sheath and stainless steel fins.

Watt densities

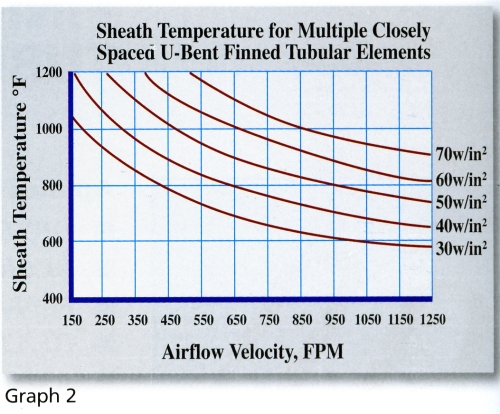

Safe watt densities that keep surface temperatures below allowable limits depend on the speed of the incoming air and its outlet temperature.

Graph 2 shows maximum watt densities recommended for a specific sheath temperature and air velocity.

Physical characteristics

The outside diameter of fins, their thickness, the spacing between consecutive fins, and the element sheath and fin material all play a major role in the effectiveness of heat transfer.

|

Tube diam. |

Fin thickness |

Fins per inch |

Fin width |

Total in² per linear inch* |

Max. sheath length* |

Outside diam. of fins |

|

0.216" |

0.020" |

5 |

0.375" |

8.30" |

240" |

1.01" |

|

0.315" |

5 |

9.20" |

1.07" |

|||

|

0.375" |

5 |

10.10" |

1.13" |

|||

|

0.430" |

5 |

10.83" |

1.18" |

|||

|

0.475" |

5 |

11.60" |

1.23" |

|||

|

*Dimensions are subject to change |

||||||

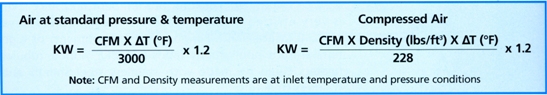

Kilowattage needed to heat air

Optional features

- Rustproof coating

- Stainless steel fins and tubular sheath material

- Nickel plating

- Special mounting accessories

- Various shapes

Mounting attachments

Threaded fittings, if required, are the standard mounting attachments supplied with finned tubular heaters. These fittings are brazed or crimped onto the heaters. For special applications, finned tubular heaters can be made with mounting brackets that have special designs.

To order finned tubular heaters, please specify...

- Element diameter and sheath material

- Fin material

- Terminal type

- Total sheath length

- Cold section at each end

- Voltage and wattage

- Bending configuration drawings

- Quantity

- Mounting characteristics and accessories (if required), and

- Special moisture-resistant seal (if required).